Power and Temperature Management System for Service Stations

Control and regulate the power and temperature of your cooling and freezing equipment in real time

Monitor your commercial refrigeration equipment with our power and temperature management system

Maintaining a consistent temperature in commercial cooling and freezing systems can be a daunting and time-consuming task. Say goodbye to the hassles with our innovative power and temperature management system.

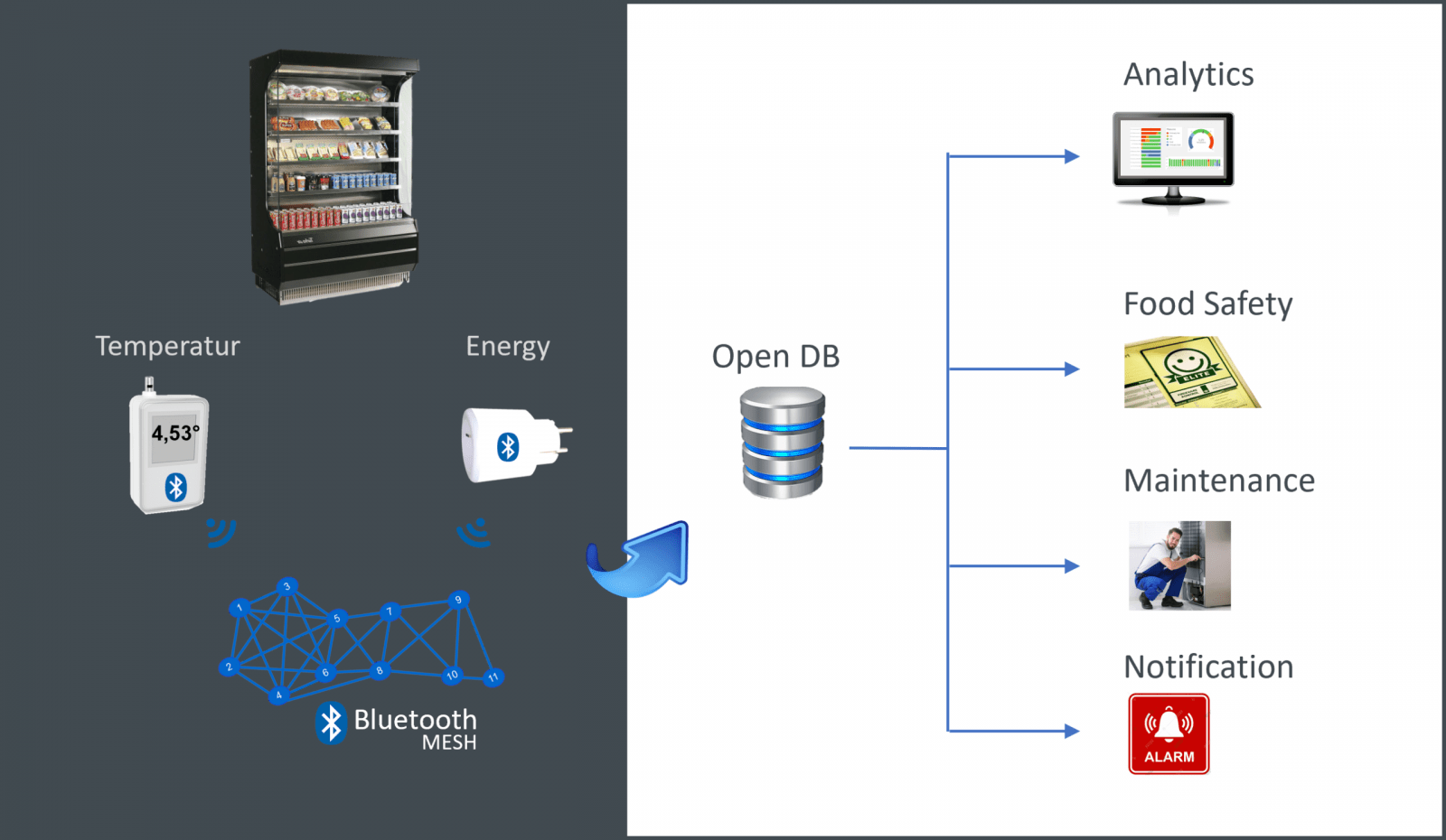

Our system comprises three essential components: a temperature sensor, a smart power plug, and a user-friendly dashboard. This means that you don’t need to invest in costly upgrades. We take care of configuring the IoT sensors and the electric plugs with our advanced AI algorithms. These devices continually transmit temperature and energy consumption data to our secure cloud server, where we filter and analyze the information.

Our power and temperature management system not only keeps you informed of any temperature fluctuations, but also alerts you to operational irregularities. You’ll receive early warnings within seconds. Rest assured, your cooling and freezing equipment will operate at peak performance, ultimately saving you both headaches and money.

Ready to experience the benefits firsthand? Don’t miss out! Book a free trial of our power and temperature management system today and discover how it can optimize your operations and reduce energy costs.

Reap the following benefits by using our power and temperature management system

Keeping precise temperatures in commercial freezers and coolers is essential for preserving the quality and safety of perishable goods. Read about some of the advantages of implementing our power and temperature management system:

Precision Temperature Control

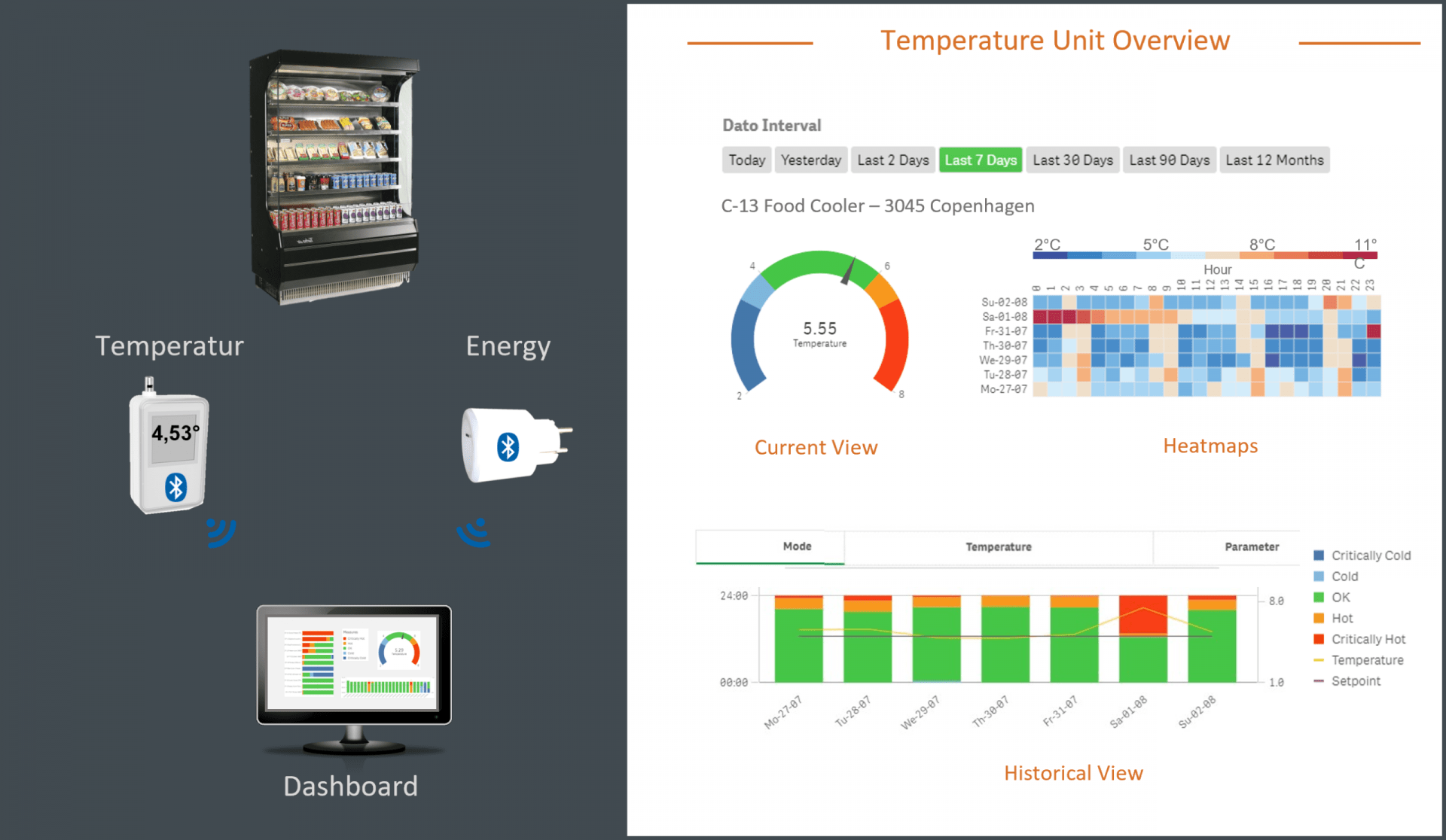

Your personnel can always access real-time power and temperature data, as well as system status. The system sends alerts and notifications if temperatures deviate from the desired range, allowing for immediate action to be taken.

Remote Monitoring and Alerts

Our IoT-based system enables real-time monitoring and adjustment of power and temperature settings, ensuring that goods are stored at the ideal conditions. This level of precision minimizes power and temperature fluctuations, reducing the risk of spoilage and improving the overall quality of stored products.

Compliance with Regulations

Service stations are subject to strict regulations regarding temperature control and monitoring. Our IoT power and temperature management system can help your service station maintain compliance with these regulations, ensuring that products are stored safely and that audits go smoothly.

Energy Efficiency

Our power and temperature management system can help you optimize energy usage in your commercial freezers and coolers. By constantly assessing energy levels and temperature conditions, our system can minimize unnecessary cooling cycles, extending the lifespan of your cooling equipment.

Historical Data Analysis

Our system collects and stores historical temperature data. This data can be analyzed to identify trends, track temperature variations, and ensure compliance with regulations and standards. This information is invaluable for service stations since they need to demonstrate proper temperature control to regulatory authorities and auditors.

Cost Savings

Investing in our power and temperature management system can lead to significant cost savings over time. By preventing temperature fluctuations, your service station can reduce product waste, saving money on restocking. Additionally, energy-efficient operation leads to lower utility bills, and the ability to address issues promptly can minimize the costs of equipment repair or replacement.

Improved Inventory Management

By providing real-time data on power levels and temperature conditions, our IoT system offers better insights into inventory management. This allows service stations to reduce overstocking or understocking issues, resulting in cost savings and improved customer satisfaction. It also enables better tracking of product shelf life, reducing the risk of selling expired or compromised goods.

Enhanced Food Safety

Our power and temperature management system features self-monitoring, which plays a crucial role in ensuring that perishable goods remain safe to consume. Your technical staff receives alerts of temperature deviations within seconds, enabling them to take corrective action before product safety is compromised.

Our power and temperature management system can ensure your oil company reaches its sustainability goals for your service stations. Request a free trial or contact us today.

The perfect solution for your coolers and freezers

When you choose EMD Service’s solutions, we monitor the temperature of your systems and the energy consumption at your service stations. This prolongs the lifespan of your devices and equipment.

- Save over 30% on energy costs

Increased food safety with temperature monitoring - Benchmark energy consumption with similar equipment

- Monitor compressor operating time and avoid breakdowns

- Easy and fast installation of monitoring equipment

- Simple overview on one display

ROI ”A service station with 15 units, has an expected total ROI of 0.6-1.5 years.”